JULIAN LILLEY tells us about a visit to Noch in 2019.

JULIAN LILLEY tells us about a visit to Noch in 2019.

Following on from our history lesson last issue, we now look back at our visit last August.

We stayed in a delightful, typically German small hotel, within a kilometre of Noch's head office and factory complex. After the usual continental breakfast, we were greeted by Dr Rainer Noch and were chauffeured to his headquarters! On arrival we were introduced to all of the staff in the office.

We were then given a whistle-stop tour of the factory starting in the large preformed layout department.

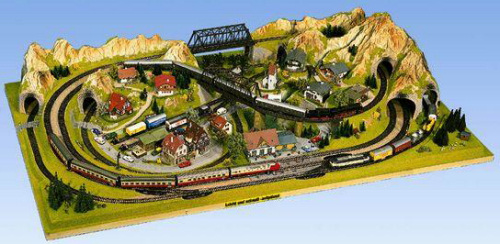

There is a wide range, some of which can be supplied almost ready to go with your choice of track. The "landscape" is a plastic formed model, installed on a stable varnished wooden frame and covered with grass. The tunnel portals and the assembly openings are milled-out. Most can have additional extensions and an under-board fiddle yard if you want to go the "whole hog".

A HO Scale layout board after fitting out

An N Scale layout board after fitting out

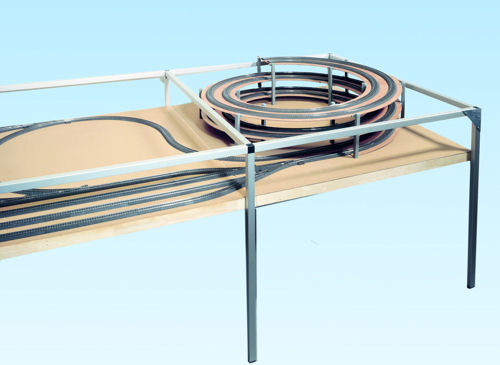

For the ultimate space saving layout, a wooden baseboard designed to fit in an aluminium frame allowing you to create an under-board fiddle yard for locomotive storage

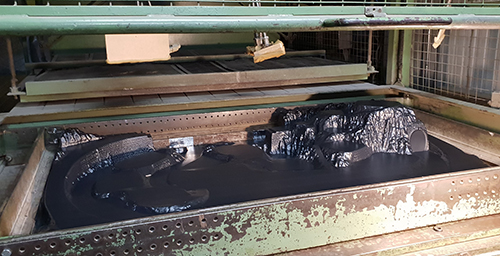

The various moulds for the extensive range of layouts

The team watch on as a layout is being formed

The operator adjusts the heat where dense moulding is needed

♫ "Ground control to Major Tom..." ♫

Layout boards by type, complete with wooden frames

Layouts which have been primed awaiting paint detail and flock to be applied

Glue being applied where grass is needed, before being worked on by the flocking machine

How the board looks after the grass is applied

Well packed completed layout boards ready for shipping around the world

In the same room the finishing of the layouts was taking place, the train sets for the person who has everything were being constructed.

If you go away somewhere you need not give up your beloved hobby, thanks to Noch's briefcase layouts. Packed in a strong metal travel briefcase in a miniature form that works anywhere, these small charming layouts can accompany you on every trip.

They include a high-quality electronic control consisting of a speed regulator a direction regulator and a plug-in power supply/battery pack.

The electrics being installed to the Interlaken Z Scale Briefcase set - locos and rolling stock extra.

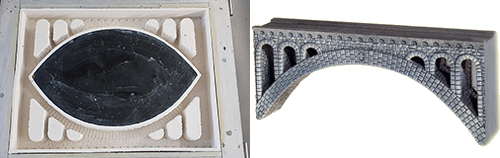

Next, we were shown the hard foam production room where everything from HOe tunnel portals to Ziterdes wargaming accessories are made. To ensure the high definition in the finished product the moulds are used no more than 50 times before being replaced.

Mould being prepared for the hard foam viaduct pictured here

As we approached the grass flocking production area more staff in space style headgear (to prevent them breathing in the fine fibres) appeared. In every room in which flock is used there is apparatus in the ceiling producing a very fine spray of water.

On one side of the room there were three large mixing drums, where specific dyes are added to the uncoloured flock to produce the many different grass and foliage colours available in the Noch range.

On the other side were huge rolls of matting, it was like being in a carpet warehouse. I counted at least seven different shades of green to suit all requirements.

Grass flock in production

Anyone need some grass matting and ballast for a large layout!?

We then left the old part of the complex and went into the new block that housed all their new high-tech equipment. There were some very exciting projects they were developing, but they are too secret at this stage to film and report back on.

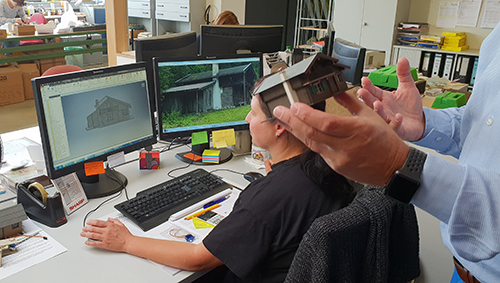

What I can say is that Noch are a massive innovator in bringing realistic laser cut buildings and accessories to our hobby.

The designer takes details from pictures of the original building and produces scale plans, which in turn results in a parts list. Instructions are then sent to the laser printer to produce the kit which builds into the model seen here in Dr Rainer's hands.

At a touch of a button it can be changed to whatever scale is required.

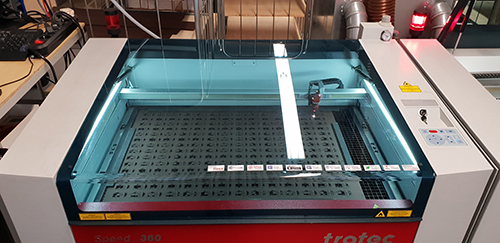

One of the laser cutting machines producing one of the hundreds of laser cut accessories

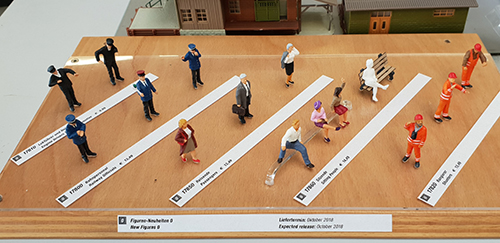

As mentioned in the previous article, the Noch figure range has become one of the most popular in the industry, and covers HO, N, O, TT, and Z Scales.

The O Scale figure range, which were released at the end of 2019

Before the end of our tour we walked passed a stack of the largest Advent calendars I have ever seen. Each "day" on the calendar comprises of parts to make a complete Christmas Market scene in OO/HO. Even the plastic tray the parts were housed in would make a great bits box after the set had been made. At the time of going to press it may be too late to give one as a present (unfortunately so... -Ed), but with no sell-by-date it will keep until next year!

Appropriately, we finished our tour in the warehouse and despatch distribution centre

In 2015 Noch installed the latest state of the art automated warehouse. The new construction of Hall 3 and the installation of the automatic warehouse was the highest investment in their company's history.

Part of the automated racking prior to being stocked

These pictures show the very clever and intuitive automated packing process and the only human visible in the whole area at that time (does that include the photographer? -Ed)

A light lunch was served from the local deli followed by a lengthy but stimulating Sales meeting covering many subjects, including Noch's first official attendance of the Warley Show at the NEC in Birmingham.

In the evening we were taken to the island of Lindau to a delightful restaurant serving traditional German food and of course alcohol. Overlooking its most famous landmark of the harbour entrance with its Bavarian lion, lighthouse and spectacular backdrop of Lake Constance and mountains, where these pictures were taken.

Lindau's old town is located on the 170-acre island itself. It is the second-largest island on Lake Constance after Reichenau. The town has centuries-old buildings, historic squares and is set in Bavaria's most south-easterly corner.

Amongst the buildings is their Town Hall, unfortunately it was too dark, and I had probably to many of the local brew to appreciate its splendour! However, it can be seen in a beautiful HO/OO kit by Faller, reference FA130902.

The main purpose of our second day was product training. This was a very hands on and interesting day where we covered the benefits and how to use/make:

Dr. Rainer introducing the product training session with Matt and Warren looking on

The room was neatly laid out with all the equipment we would need including a Noch branded apron with waist ties that even managed to go around my girth, much to my surprise!

We then had the challenging task of replicating their chief modelmakers work. Having never used the Gras-Master before, and being ultra-competitive, I listened to every syllable he said in order to try and gain an edge over my colleagues.

Using a small preformed hard foam base, we first made a small pond. Noch's N60873 Artificial Water is a one-part liquid that can be easily applied using a hairdryer and sets quickly. If a mistake is made, it can be reworked by heating again.

After a coffee break, allowing the pond to harden, we were then shown how to use their flocking machine.

These pictures below shows how easy it is to use:

Noch's chief modelmaker Karl-Heinz Echteler demonstrating how easy it is to use the Gras-Master 2.0

I will go into more detail on this wonderful tool in a future issue but for now, being a salesman, I can't resist listing its key selling point.

The advantages of the Gras-Master 2.0 for perfect model landscaping:

My finished model made in just a few hours - as an inexperienced scenic modeller I was proud of it. No, I did not pinch the Karl-Heinz's one for the photos!

Sonja Bernhard from Noch demonstrating the benefits of the new Gras Master at Warley in November 2018

After giving our thanks for their excellent hospitality we returned to the UK the following day via Munich.

Once back in the UK, our Southern Area Rep Kevin gave other Gaugemaster staff a training session on how to use Noch scenics

I hope have whetted your appetite to look in more detail at one of the world's leading model scenic accessory manufacturers. For more, there is the N71120 2019/2020 Noch Catalogue, with lots of tips and ideas in English to make your layout or diorama special.