Deluxe Materials are a manufacturer and suppllier of Glues, Adhesives and other modelling products making even easier to create the models and layouts of your dreams.

A long time ago, 1973 to be precise, in a distant town in the north of England, a young couple fresh out of university began their careers. John and Vivienne Bristow married that year. John’s first job was with Vickers shipbuilding working with epoxy resins and Vivienne was a science teacher. John was already a keen modeller, building and racing model boats and he was not always satisfied with the products available. With very little spare money to spend on his hobby, John decided that the way to go was to buy in bulk and then sell on. But John did not want to buy and sell other people’s products; he wanted to invent, develop, and produce his own.Supply of silicone tubing was probably the first venture along with the invention of metal filled silicone tubing, with improved heat transfer and extended life. And when Ron Irvine, of Irvine Engines, asked John if he could produce an epoxy glue, John’s reaction was ‘of course’ and that was the beginning of Deluxe Materials. So much has happened in the last 50 years that John and Vivienne can only tell their story with a glimpse of all the hard work, events, people, and stories, often funny, always interesting, that have made Deluxe Materials what it is today.

As you can see, Deluxe Materials began with no plan. It just happened and evolved. John and Vivienne tell their story.

John, Vivienne, and world model boat championship trophy.

The early days were difficult but fun and our scientific backgrounds stood us in good stead to understand the chemistry and development of our products. Our business began in a flat in Friar’s Lane, Barrow in Furness. This was 279 miles away from our first customer, Irvine Engines, in High Barnet. It was a challenge for us to make deliveries there as we did this ourselves in our old Ford Cortina. On our first delivery we even had to ask Ron Irvine for the petrol money to get back home. We are pleased to report that we can now afford to pay our carrier companies to deliver for us.

Some of the Irvine Engines team.

Our other challenge was space, or lack of. We came home one lunch time to find that our neighbour, the butcher next door, had received a large consignment of plastic bottles for our Speed Epoxy. These we piled into our hallway making it almost impossible to squeeze in ourselves.

John and Vivienne Bristow sit with their loyal team members.

Things have changed somewhat since then. We are still a small company, now based in Hampshire and mainly serving hobby markets including aeromodelling, model boats, plastics, diorama, dollhouse, and model railway. In addition, our products have found their way into electronics, artist studios, film, and TV. Our Scenic Snow even found its way into a Selfridges window scene one Christmas.

Two of the Deluxe Materials Units.

We have expanded internationally, selling into around 40 countries worldwide through our distributors, some of whom have been with us from the very early days. We have gained many loyal customers who believe in our products and developed many friendships especially with Gaugemaster our Uk distributor. (And it has been an absolute pleasure working with John, Vivienne and the Team - ED).

United we stand. Gaugemaster and Train-Tech have had a long and fruitful relationship with John and his team.

We are also particularly proud that now new customers come to us, as was the case with Horizon a major US distributor in 2010. Our challenges have included management of this overseas distributor network along with supporting the trade and we always enjoy meeting them at shows.

Cheltenham Model Centre's Trevor and Rachel stand with John Bristow while holding their latest catalogue highlighting all the wonderful products Deluxe Materials offers.

We continue to uphold our values by producing the highest quality products that modellers need and at the same time, helping to educate in the benefits and use of those products with many ‘how to’ articles in magazines and our catalogue. (Many of which John and the team have kindly let us incorporate into our Knowledge Base under Model Making Materials.)

Here we see an article showing just how easy and effective the Deluxe Materials View Glue is.

We are committed to making products safer for the modeller and for the environment and we have expanded in the range of products we make, adhesives, gluing accessories, and scenic products.

We are often asked how we develop our products. Hard work is the answer. Ideas may come when we see a need ourselves or very often from other modellers and experts who have helped us along the way. Developing from scratch is often a challenge.

The market called for good, well packaged plastic glues so we have developed a range which includes Plastic Magic for which we designed a stable glass bottle and cap and two brushes. Its features include great solvency and ability to bond a wide range of plastics making it unique in the market. The nature of the chemical and design of the bottle reduce evaporation and odour in the home or workshop.

With low odour and slow evaporation compared to competitors, Plastic Magic is capable of glueing a vast array of plastics

We noticed the problems of track cleaning and so we developed Track Magic that when applied to the track would loosen track dirt and dissolve it away to leave a better conducting surface. Here we used some novel chemistry employed in aviation fuel to assist conductivity.

Track Magic loosens and dissolves dirt where other track cleaners do not.

One of the most difficult products to develop was Ballast Bond, a highly penetrating glue for bonding granular material such as ballast. The product needed to work its way in and not move the ballast granules. Here we used chemistry for bonding rock granules and sand. We worked through 62 formulations before we were happy to release the product. Such was the demand that when we released it in USA, we had to then offer a bigger refill pack!

Original promotional video for Ballast Bond.

Innovation is an important aspect of our work and success. An example of this is our Precision Plastic Glue. The idea for this came from a very progressive dealer - Russell Rowe. He asked us to develop the glue product so that it can be legally posted and without risk of needle damage in transit; Russell was also worried about build-up of smell from flammable vapours in his store. We adjusted the glue’s fluidity and anti-clog properties and made it non-flammable. We designed the bottle to be comfortable to handle and to house the needle applicator, for safety and ease of transport, in a recess at the back of the bottle.

Precision Plastic Glue is supplied with a needle-fine applicator for precision application.

The product creation process, then, is to start with a concept, research a brand, develop the technology, test with the help of expert modellers and trial at model shows, whilst at the same time developing the packaging and labelling.

Ian Mcgonagle is just one of a variety of people chosen to test some new products.

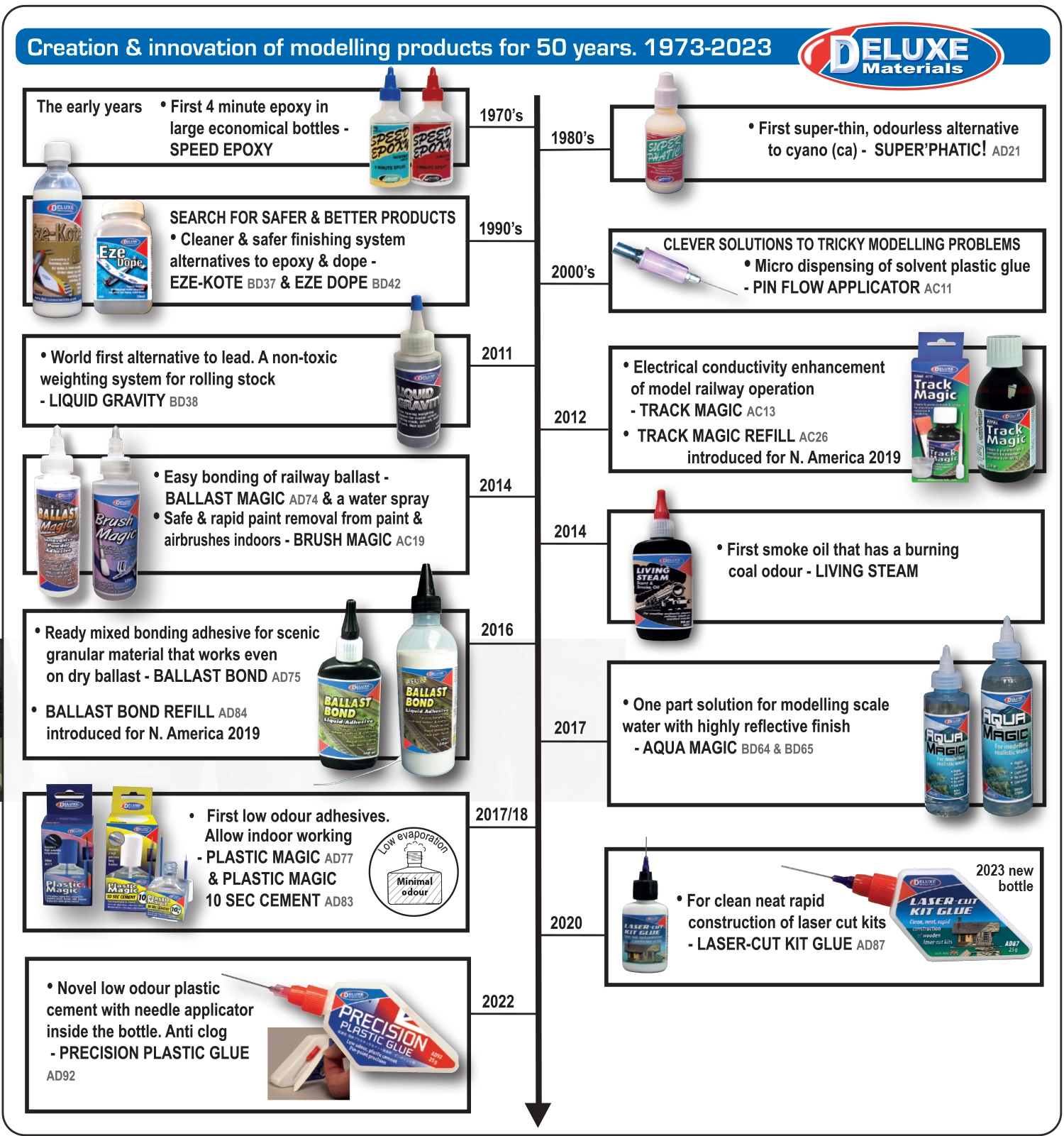

There is much to consider, legality, health and safety labelling and translations into several languages when bringing a new product to market. Here are some of the significant developments over the 50 years of which we are most proud.

A timeline of some significant product developments over the years.

We have had fun during our 50 years. We have enjoyed attending model shows in the UK and abroad, opportunities for us to meet those who buy and use our products.

From left to right: Model Railroaders at Amherst, USA 2023 and George Dent with John Bristow.

George Dent, railway modelling authority and a great supporter of our products, has been a regular visitor to our stand and great consultant along the way often kindly publishing our work eg on Scenic Rust and creating rust effects.

Just one of the many projects George Dent has undertaken for Deluxe Materials. This one shows off the effects Scenic Rust can create.

Thank you George for all your help and inspiration.

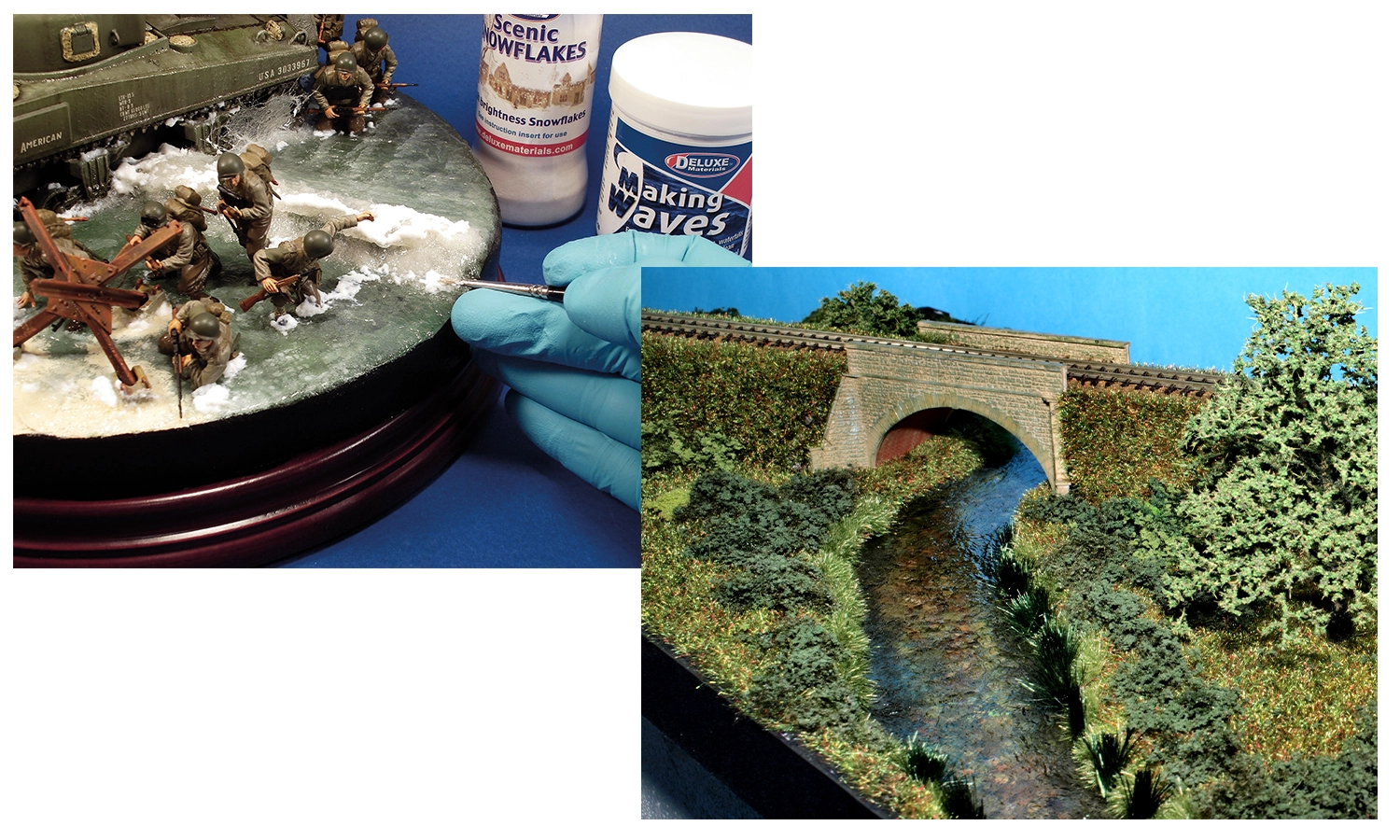

By using a selection of the water products in the range, different effects can be created. The 'Devon River' scene is created using Solid Water and 'D-Day at Omaha Beach' utilizes Making Waves and Scenic Snowflakes.

We enjoy meeting expert modellers who are happy to show us their work such as this European station where our Living Steam smoke oil has brought a new level of realism with its lingering smoke and the aroma of burning coal.

Living Steam is used to create realistic visuals and scents of smoke..

We have learnt a lot over the years including the importance of careful proof reading. We value and admire those who make hard decisions because they believe there are better solutions, and we value worthy competitors as those companies encourage us to improve and to be different.

It would be wonderful to end this account with acknowledgments and thanks to all the people who have helped us over the years. I would however like to say a special thanks to our friends at Gaugemaster. We have purposely not included individual names as there are so many. But we say thank you to our team at Deluxe Materials, past and present, our customers, magazine editors, modellers, show organisers, all those who have helped develop and test our products.

What of the future? Wherever modellers meet, we hope that our products will be highly regarded and talked about in a positive way. Deluxe Materials will continue to serve the modeller for at least another 50 years! Perhaps you are the person who will make this possible? If you are, then get in touch.

Foot Notes:

All images supplied by and copyright John Bristow/Deluxe Materials Ltd. Used with permission.

We would like to thank John and Vivienne and all their contributors for allowing us to publish and host this article on our Knowledge Base and look forward to working just as closely for many years to come.

For more articles like this, and many others; don't forget to check out the Gaugemaster Knowledge Base.