With Digital Command Control becoming more and more commonplace in layout operation, it was only a matter of time before more and more interesting elements were introduced by manufacturers. The British market made the leap when Train-Tech introduced the Smart Screen.

The Train-Tech Smart Screen is seen here in action on a model railway layout, displaying the time and destination of the next train to arrive at the platform.

For those of you who haven’t come across the product yet, the Train-Tech Smart Screen is a miniature screen designed to mimic the display screens found on platforms, on the side of trains, and even those in buses or coaches, as well as any other location these screens are found. Note: you can also buy the Smart Screen as part of a Twin Pack or a Starter Pack.

The Train-Tech Smart Screen being used at a model station platform, on the side of a train and at a roadside to display messages for drivers

The Train-Tech Smart Screen is not simply a module that lights up. Primarily designed for OO Scale use, it can be fully programmed to display any message that you want. If you’d like them to display the upcoming departures from your platforms, they can. If you want them displaying the destinations on the side of a coach, they can. The units do require a DCC Controller to program them, but once programmed, they’ll happily operate from a clean 16v AC supply. Train-Tech has a free downloadable PDF to help you to plan out the text for your display boards.

Before installing the screens, you need to decide what they’ll be doing. Then, decide what you’d like the unit to say. This bit is key as if it’s not properly planned out, the following stages can become frustrating and repetitive. We’ll show you how to set up a Smart Screen with a platform mount to show the next trains departing from our platform.

It is always good when planning your layout to have in your mind aspects of the layout which affect how it will be modelled. Consider drawing a rough map of the surrounding area of your layout to help you plan this out to make sure your station signs correctly reflect the area surrounding the model, you don't want two trains running in different directions heading to the same place! It will also help when positioning any road signs around your layout too.

For added realism, consider the time you’ll have your trains arriving and departing. Most model scenes take place during the morning or evening, so think about what makes most sense for your layout. For example, you wouldn’t want your times set at a point in the evening if you have a postman delivering your post a few streets away from the platform.

The Smart Screens come pre-fitted with six solder pads on the back. Care is needed when soldering these - if too much heat is applied, the internal connections may become damaged. A small quick touch with a 25w Soldering Iron should suffice. There are two connections that everyone will be using, which are marked with a letter 'P'. These are your power input. Simply solder a wire onto each of these and you’ll be ready to program.

A close-up of the back of the Train-Tech Smart Screen. The screen is fitted with a plastic cover on the front - do not remove this until installation is complete

In this example, we won't be using anything other than the 'P' pads. If you’re interested in exploring other uses, attach the wires to the additional terminals (excluding the 'L' terminal) and leave the cables loose but isolated for future use.

Now that you’re connected, the programming can begin. Firstly, note how the Smart Screen programs. The unit needs to be connected to the MAIN TRACK output of your controller, and not a programming track output if it has one. This is due to the Smart Screen being programmed by way of loco accessory commands.

The default address of the Smart Screens is 55. If you have a locomotive on your layout with this number, you’ll need to change the address of the Smart Screen to another number. For the two shown here, the numbers 9991 and 9992 were chosen as they are completely different to any locomotive running on our layout. To change the address of the Smart Screens, simply refer to the enclosed instructions.

Once this is done, you’ll need to call up the Smart Screen address on our digital system. As previously mentioned, the Smart Screen addresses are locomotive addresses, so simply select them as you would a locomotive. In this case, select locomotive 9991 for the Smart Screen destined for platform 1, and 9992 for the Smart Screen on Platform 2. On initial start-up, the Smart Screen will display a pre-programmed message. To begin programming, activate Function 8, and this will bring you to the following screen:

The Smart Screen fitted into the Smart Screen Right Hand Post Housing, displaying ‘F4 edit message’ and F5 ‘edit controls’

Here, you have the option to edit the messages stored on the Smart Screen or edit the controls. For now, you simply want to edit the messages. Be aware that once you pass this step, the pre-loaded demo message will be permanently deleted. Activate Function 4. You will now be faced with the following screen:

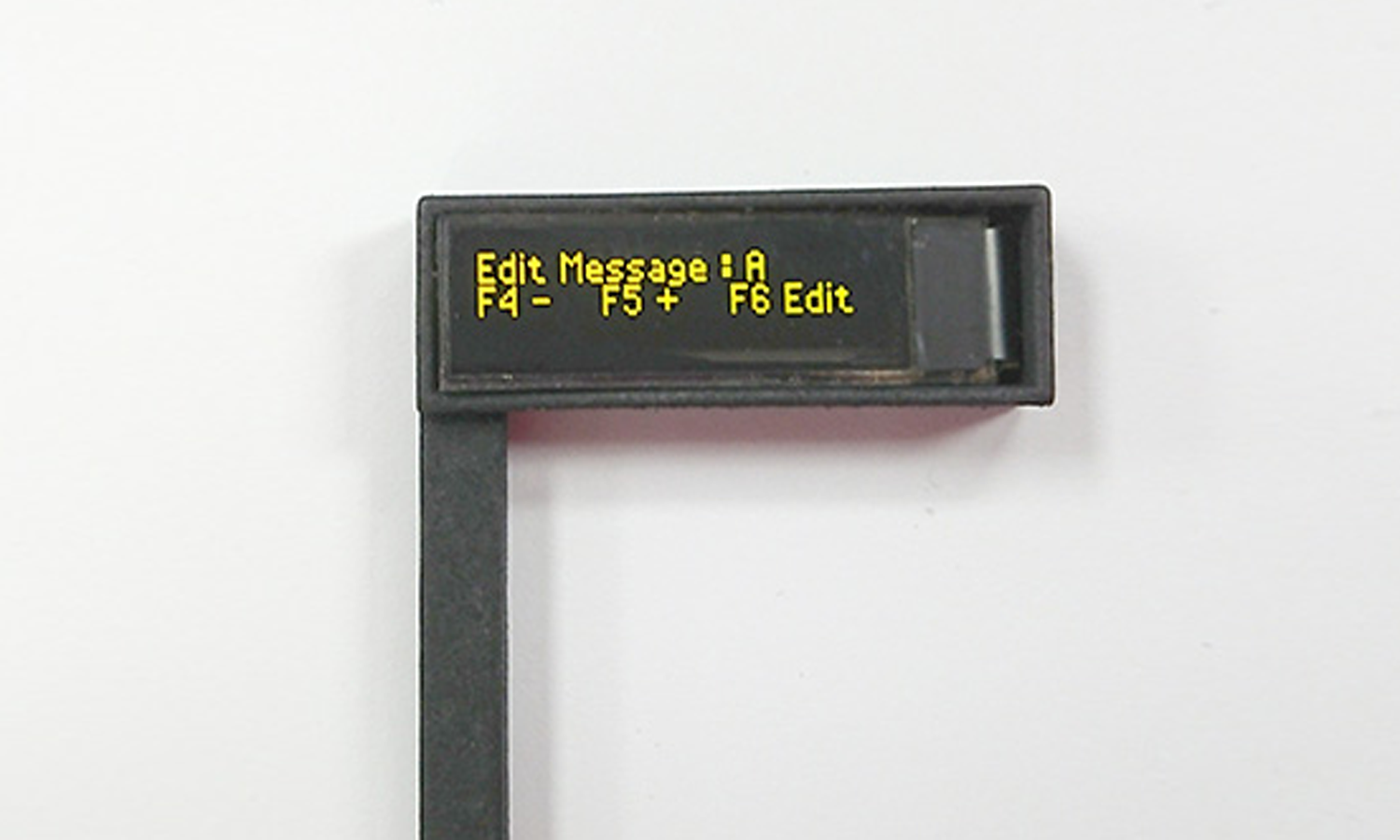

The Smart Screen displaying ‘Edit message: A. F4 - F5 - F6 Edit’

This screen is now asking which message you wish to edit. For your first message, you need to simply Activate Function 6. If you’re adding additional messages, simply use functions 4 and 5 to cycle through the letters A-J to choose the desired slot.

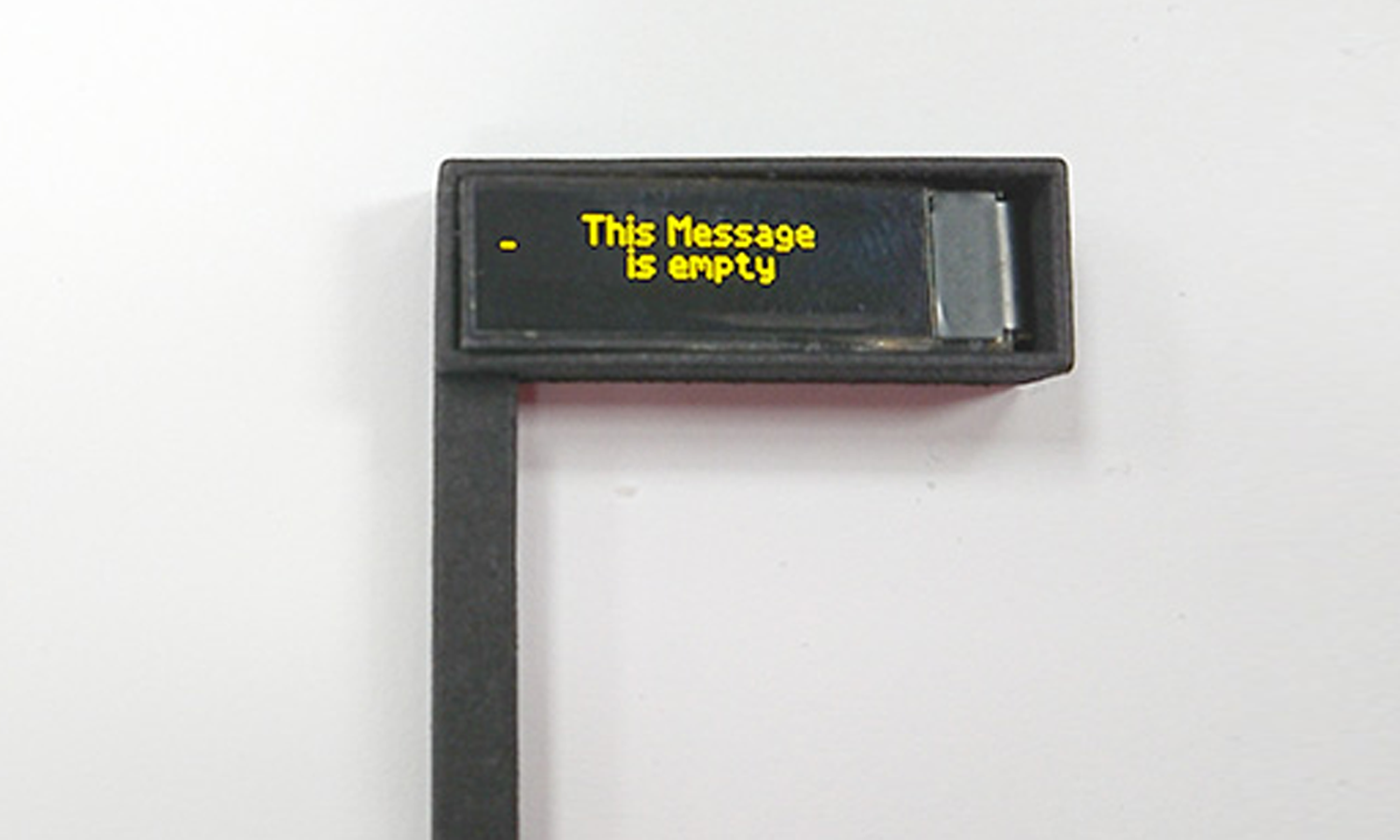

You can program one message in each of the letters A-J, making 10 in total. The following screen will now appear.

The Smart Screen displaying ‘This Message is empty’

Now is the time to start adding the first line of your message. Use the Functions as described below to add your messages:

This line will only display what’s shown on the screen. If you wish to insert a clock, do this to begin with so that you know how much space you have for your text. Once the line is complete, simply fill the remainder of the line with spaces by pressing Function 1. Once this is done, the cursor will automatically drop to the second line.

The Smart Screen displaying ‘17:38 Eash Lye’

Simply repeat the process as described above for the second line of text. Note that this line can hold up to 137 characters. Once the initial amount has been entered, the text will disappear to the left. Don’t worry, it’s still there and, once the line is complete, the Smart Screen will display this as a running banner as seen on real platform screens. To end the line of text, add a few extra spaces. This will make sure there’s a gap between the final letter and the first letter when the scrolling line repeats.

Once that line of text is complete, all you need to do is activate Function 8. The unit will then jump to displaying your message. If you want to add further messages for the screen to cycle through, simply repeat the above process.

Please Note: Analogue users will need access to a DCC System to initially program the Smart Screen, but afterwards, you’ll only need to power the unit. Please contact us if you are having any issues with accessing a DCC controller and we will see what we can do to help.

Feel free to use the text in the examples below if you haven’t quite decided what you want your destinations and text to say yet, and just fancy having a go.

One option is to control the Smart Screen via track sensor. Here, we explain how to use the sensor to change the board from showing the upcoming train to announcing its arrival.

Video showing a train approaching the Train-Tech Smart Screen, which is operated via a track sensor.

The first thing to do is to program up your Smart Screen with the required messages. You’ll need the messages stored in Message Slot A and Message Slot B. Start by programming the message into Message Slot A. This is the message that will be displayed prior to the train arriving. In our example I have set the message to read:

12:58 London Victoria

Calling At: Ford, Arundel, Horsham, LONDON VICTORIA

Message B will be displayed as the locomotive activates the sensor. This reads:

**STAND CLEAR**

TRAIN IS ARRIVING

The final stage of the programming is to assign the control a DCC Address. Although it won’t be using this address, this will make sure the Smart Screen doesn’t cycle the messages without the sensor being activated. To do this:

For Gaugemaster Prodigy users*:

*For users of other systems, consult the manual of your controller on operating accessories.

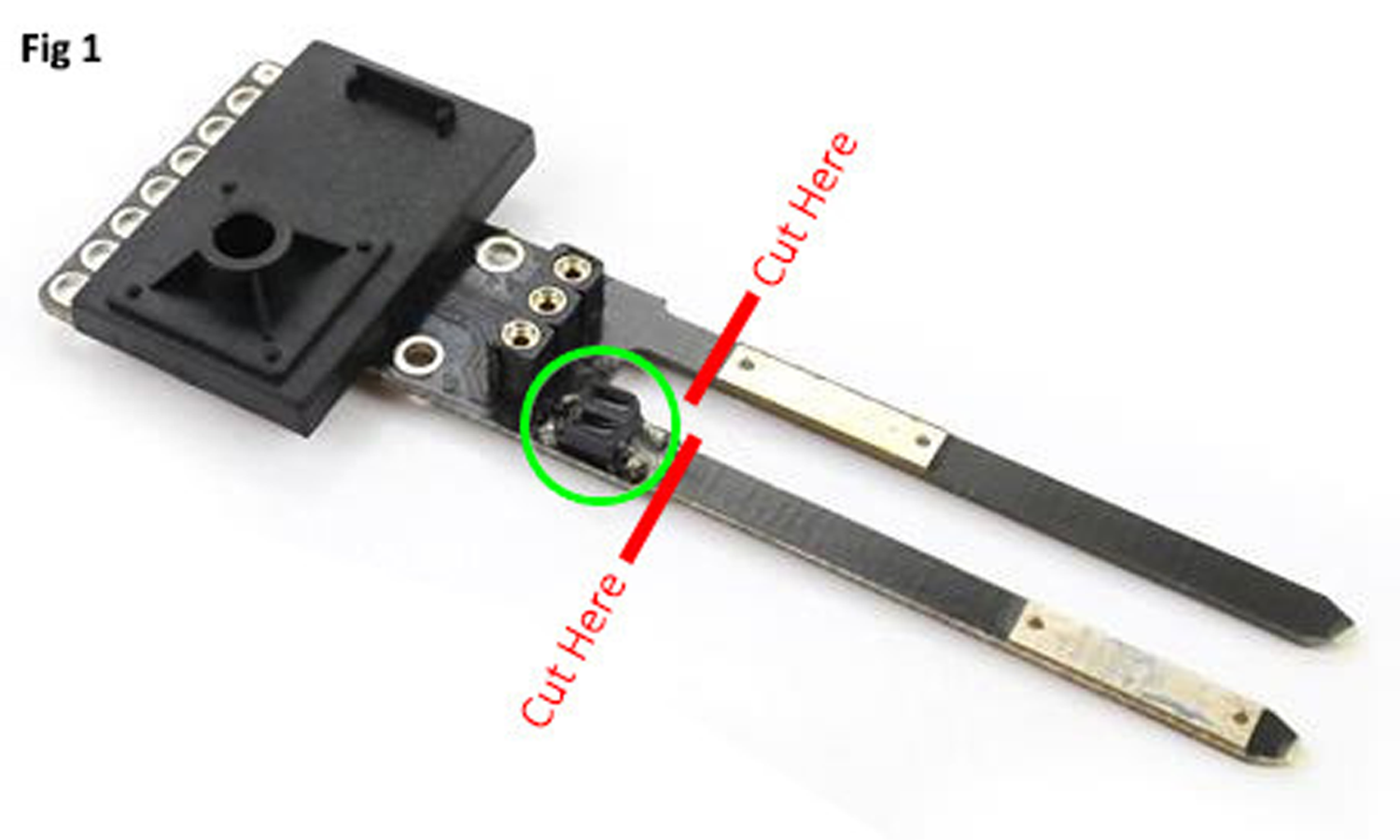

Once the above is programmed, it's time to add the additional TTST10 Track Sensor to the layout. There’s a small difference in installation depending if you’re an analogue or digital user:

A close-up of the legs of the track sensor. Red lines indicate that they should be cut along the dotted lines on the PCB.

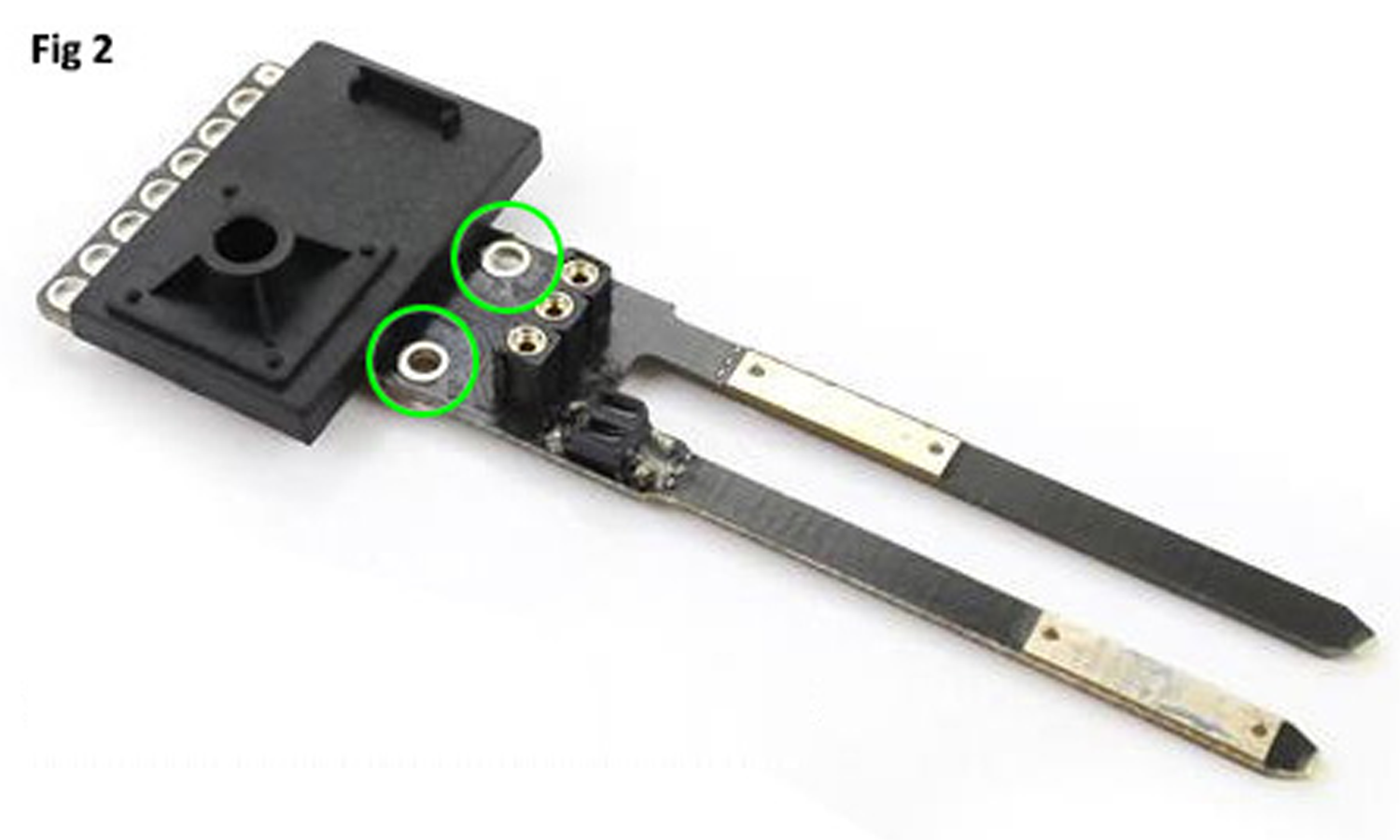

A close-up of the track sensor’s solder pads.

Finally, for both analogue and DCC users: the last step is to connect the Sensor to the Smart Screen. On the back of the Smart Screen, there are additional solder pads marked A and B. A final wire needs to be attached to the solder-pad marked A. Once this is done, simply push the other end of this wire into the middle hole on the track sensor.

When this is all connected, you’re ready to go. Power up the layout, and as your train passes the sensor, you’ll notice your message change. After a few moments, this will revert to the previous message and begin the cycle again.

Option 2: Route Setting (DCC Applicable Only) Now let’s look at how to change the screen depending on the route the points are set to. This one is for DCC users only, as it requires the activation of the points via digital control.Now let’s look at how to change the screen depending on the route the points are set to. This one is for DCC users only, as it requires the activation of the points via digital control.

Video of the Smart Screen displaying the next service to call at a station, which updates once the train passes through.

The video above shows the Smart Screen displaying a message detailing the next service to call at this station. We have a train due to travel through our station and one that will be heading down the branch line after stopping. The screen will change to show the branch line service once the point has been thrown. To program this scenario, you’ll need to use two Message Slots. In the previous example we used Message Slots A and B. For this example, we’ll be using slots C and D.

Message Slot D is programmed to display the following:

12:58 LONDON VICTORIA

Calling At: Ford, Arundel, Horsham, LONDON VICTORIA

Message Slot C is programmed to display:

12:51 WORTHING

Calling At: Angmering, Goring, Durrington, WORTHING

Finally, you need to assign the address the change is going to be controlled by. In this case, it’s the throw of the point. Our point has been set up under accessory number 1. Set the Smart Screen to respond to this by selecting the smart screen address (the default is loco 55) and activating Function 8, then Function 5, then Function 5 again. This will take you to the following screen:

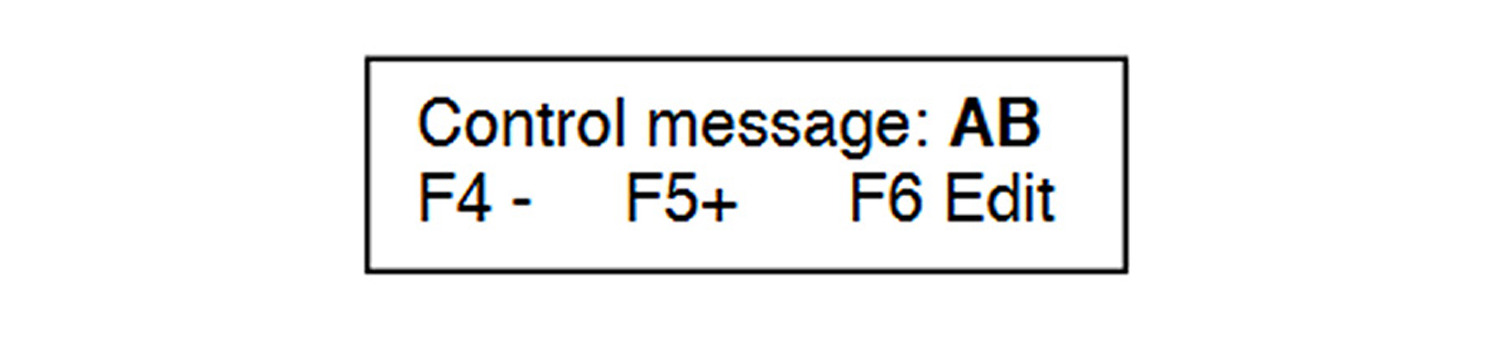

Text displaying ‘Control message: AB. F4 - F5+ F6 Edit’

Now, using the Function 4 and Function 5 buttons, scroll through the list of pairs until the one you’re using is on the screen. In the above example, we pressed Function 5 once to change the displayed pair from AB to CD. Once the correct pair is selected, press Function 6.

The Smart Screen will now be waiting for you to activate the accessory you wish to bind the Smart Screen with. For Gaugemaster Prodigy users:

For users of other systems, consult the manual of your controller on operating accessories.

Once this is done, the screen will save the command and default back to the operation screen. Now you’re set up and ready to go. You can add additional messages activated from different accessories by using another pair. For example, we are using pairs C and D combined with a point in the above example - you could add a second pair of messages in E and F to change when a second point is thrown, or a signal is set to clear. You could set it so that the Smart Screen changes from displaying the destination board to displaying ‘Please Stand Back This Train is Scheduled to Leave’ when the signal is set to green.

Here, we’ll look at how to control the Smart Screen from locomotive functions. You can change the display when you activate a specific function of a locomotive, which is perfect if you’re running your layout to a timetable.

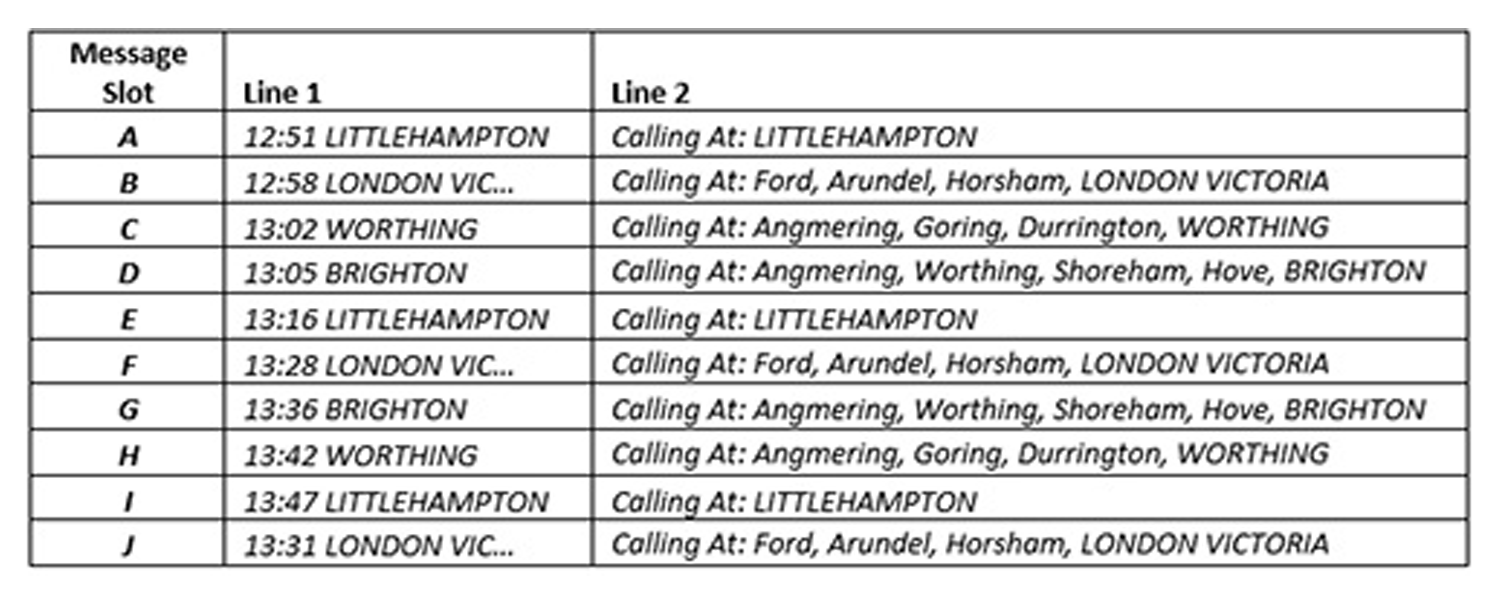

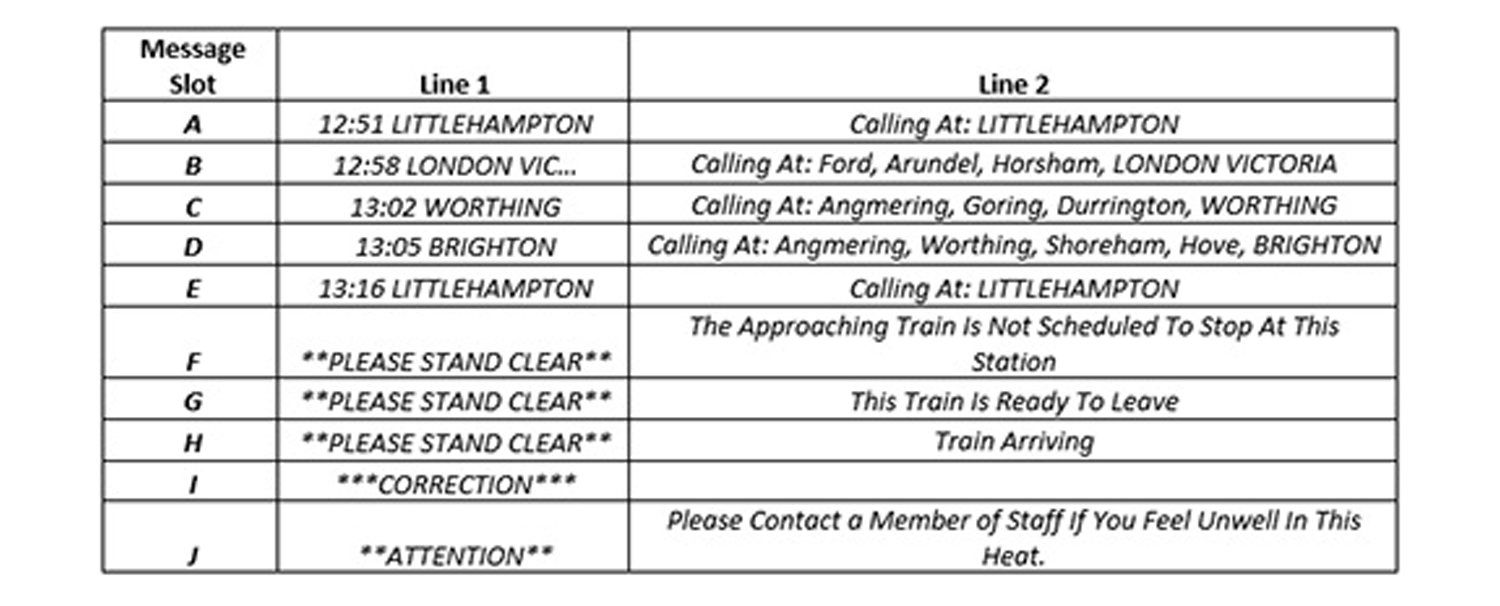

Using the function commands of a designated locomotive number, you can activate and display any of the 10 Message Slots (Message Slots A through to J) at any time. To set this up, you just need to fill the Message Slots with your required Messages. Example 1 below shows purely a list of timetabled departures:

Table showing different options for programming message slots A to J. Line 1 should display the train time and end destination. Line 2 should display where the train is calling.

The second example below shows a mix of time tabled trains and possible warnings:

Table showing options for warnings to program the Smart Screen with. For example, Line 1 could contain ‘Please stand clear’, while Line 2 states ‘The train is ready to leave’

Once your messages are programmed in, decide which loco address you wish to use to control the messages from. We suggest 99, as this number is not normally one a loco would be numbered to, but the choice is yours. You’ll need to set the Smart Screen Address to your chosen Address. Please be aware that you must set it to an unused address, and one that’s different from the address already set in the unit for its programming address.

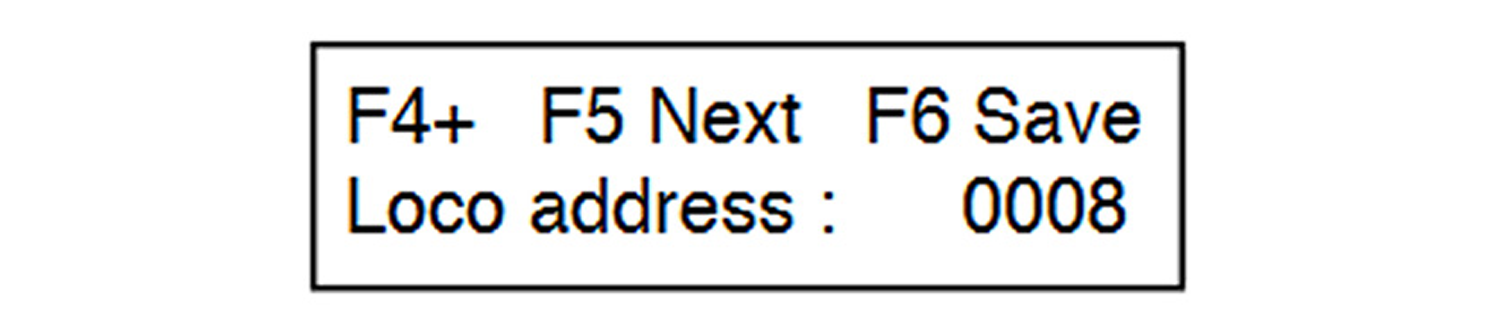

To set the control address, simply activate Function 8, then Function 5, then Function 5 again. This will then take you to the following screen:

Text displaying ‘F4+ F5 Next F6 Save. Loco address: 0008’

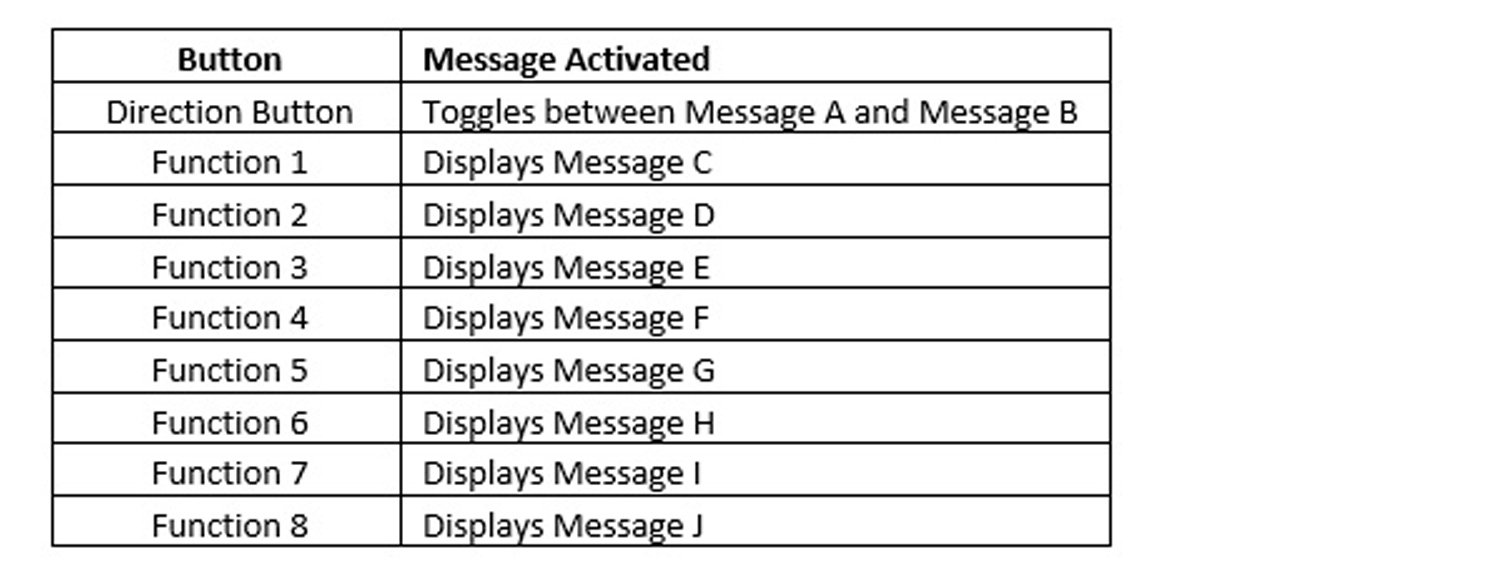

Now use Functions 4 and 5 to adjust the on-screen number, pictured as 0008, to the desired number, then activate Function 6 to save. In our example, we’d have changed this to number 99. Now you’re all set to go. To activate the different screens, simply call up the locomotive with the number chosen (in this case number 99), and activate the screens by pressing the buttons outlined below:

Table showing the different options for programming the Smart Screen. The direction button can be used to toggle between message A and message B. Function 1 to Function 8 will activate messages C to J respectively

Next, let’s explore controlling the Smart Screen from an external source. This could be for a variety of options: for example, a push-button switch, a reed switch, a relay or even a servo. This example shows how the Smart Screen could be controlled by either a Push-Button Switch or a Reed Switch.

We have a freight locomotive due to travel through our station, which won’t be stopping. As is customary on the mainline, a warning flashes up telling all passengers that the train is not stopping and to stand clear. The screen changes to this once the push button has been activated and allows the non-stopping service to continue through the platform before the screen reverts to its original display.

The screen is programmed up in the same way as in Option 1. The first thing to do is to program up your Smart Screen with the required messages. Here, we’ll be using the messages stored in Message Slot A and Message Slot B. Start by programming the message into Message Slot A. This is the message that will be displayed prior to the train arriving. In our example I have set the message to read:

12:58 LONDON VITORIA

Calling At: Ford, Arundel, Horsham, LONDON VICTORIA

Message B will be displayed as the Push Button is pressed. This reads:

**STAND CLEAR**

THIS TRAIN IS NOT SCHEDULED TO STOP AT THIS STATION

The final stage of the programming is to assign the control a DCC Address. Although it won’t be using this address, this will make sure the Smart Screen doesn’t cycle the messages without the sensor being activated. To do this:

For Gaugemaster Prodigy users:

For users of other systems, simply consult the manual of your controller on operating accessories.

To complete the set-up, all that is needed is to install the switch. This can be installed wherever you like on your layout. Then, attach one side of the push button switch to the A terminal on the back of the Smart Screen, and the second wire to the C terminal. Once connected, power on the Smart Screen and enjoy.

For DCC users both Options 1 and 2 can be combined. All you need to do is set them up as outlined above, making sure the data in Option 1 uses Message Slots A and B, and the data in Option 2 is in Message Slots C and D, and you will happily find that both control methods can be worked together.

You can also combine these with additional inputs as described in Option 4.

For Analogue and DCC users, you can combine Option 1 and Option 4, using both the track sensor method and an additional input device. There are many options with this, so just have a play.

Once you’ve programmed your Smart Screen as you require it, it's simply time to install it into the location you want it. Once attached in place, connect to either your DCC power bus or a clean 16v AC power supply and enjoy the fruits of your efforts.

The Smart Screens are available singly for those wanting to install just one, but they also come in packs of two to aid modellers who have two platforms or want to put a screen on each side of a coach.

Train-Tech produces a range of enclosures for the Smart Screens including post mounts and a hanging mount. The post mounts are designed for free standing departure boards like those found at station platforms, and the hanging mount is a simple box to fit around the Smart Screen, allowing it to be hung or mounted in a coach, or even on a wall.

The finalised Smart Screen in place and powered up next to the platform shelter of a model station

If you have any questions about the Train-Tech Smart Screen, our team are more than happy to help. Get in touch today.

This article has been written by our staff here at Gaugemaster, drawing on thousands of hours of modelling experience. Each article has been written to make it easy for everyone from beginner to expert to learn and expand their own knowledge base. If there is something you would like to see covered, feel free to contact us to suggest a topic - we’d love to hear from you.

For more articles like this, and many others; don't forget to check out the Gaugemaster Knowledge Base.